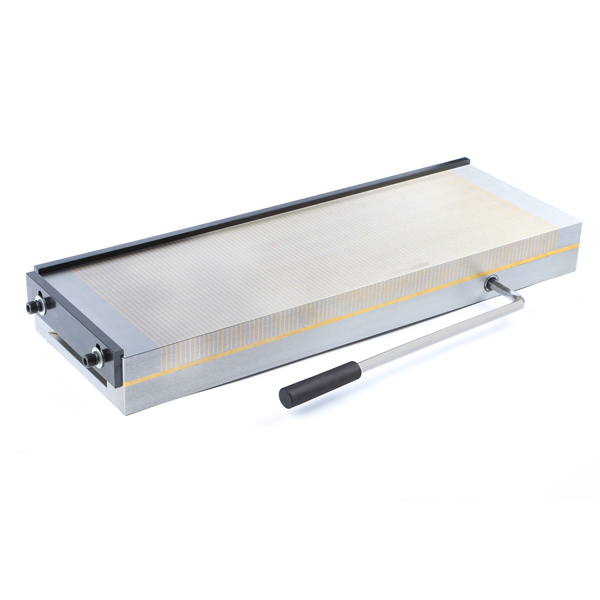

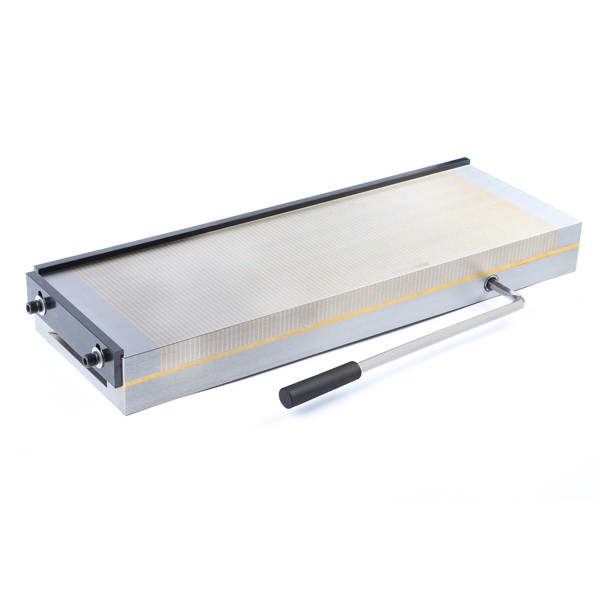

Fine Pole Magnetic Chuck for Surface Srinder

Tool Bees supplies high quality magnetic chucks manufactured according to highest standards and are available in most common sizes from stock,magnetic chucks are modern devices that replace vices, mechanical clamps, and fixtures, which accelerate your work during machining ferromagnetic materials.

Magnetic chucks can save a lot of time by clamping and unclamping machined components, while also making the workpiece accessible from 5 sides without damaging the product.The goal of using magnetic chucks for work holding has become popular in manufacturing facilities across the globe.

Workpieces for machining are traditionally held in place using vises or fixtures, but the blank, casting, or forging can also be held with enough grip to allow milling, turning, drilling, or grinding. Magnetic chucks have been commonly used in surface grinding applications, but are now also being used in general machine shops.

| Order No. | Dimension | Magnetic | Spacing | Weight(KG) | ||

| (MM) | Force | (IRON+COPPER) | ||||

| L | B | H | 120N/CM² | 1.5+0.5 OR 1+3 | ||

| TB-A13-1510 | 150 | 100 | 48 | 4.5 | ||

| TB-A13-2010 | 200 | 100 | 48 | 7.5 | ||

| TB-A13-1515 | 150 | 150 | 48 | 8.5 | ||

| TB-A13-2015 | 200 | 150 | 48 | 11.3 | ||

| TB-A13-3015 | 300 | 150 | 48 | 16.5 | ||

| TB-A13-3515 | 350 | 150 | 48 | 19.8 | ||

| TB-A13-4015 | 400 | 150 | 48 | 22.6 | ||

| TB-A13-4515 | 450 | 150 | 50 | 25.5 | ||

| TB-A13-4020 | 400 | 200 | 50 | 31.5 | ||

| TB-A13-4520 | 450 | 200 | 50 | 35.5 | ||

| TB-A13-5025 | 500 | 250 | 50 | 45 | ||

| TB-A13-6030 | 600 | 300 | 48 | 72 | ||

| TB-A13-7030 | 700 | 300 | 48 | 85 | ||

Benefits of magnetic chucks

The benefits of magnetic chucks include:

Reducing setup.

Increasing access to the many sides of a workpiece.

Simplifying work holding.

Magnetic chucks easy to operate

Our advantages bying supplying magntic chucks :

* High Quality Guaranteed magnetic chucks

* Magnetic chucks with competitive price

Usage method

1. suction cups should be cleaned before use to avoid scratches affecting accuracy.

2. Place the workpiece on the sucker table, then insert the wrench into the shaft hole and rotate 1800 to ON clockwise, then suck the workpiece for machining.

3. use ambient temperature at -400C–500C. No knocking is necessary to prevent magnetic reduction.

4. if the workpiece is finished, insert the wrench into the shaft hole and rotate it 1800 times along the counter clockwise to “OFF”, then the workpiece can be removed.

5. finish the working face with antirust oil to prevent corrosion.